HVAC-Systems

Gföllner Klimatechnik GmbH – making humans and their machines feel good

The Gföllner group climate technology team was founded in 2006 and has since focused on the development, procurement and planning of tailor-made solutions for cooling rooms with a high thermal load, as can predominantly be found in technical container construction, for example, in e-homes or the construction of electrical systems.

This way, we are able to fulfil integral solutions for complex and customers-specific requirements in the HVAC area and offer this as a complete package. These solutions, obtained from one source, also have the crucial advantage of a carefree package for the system operator, which is coordinated centrally by us from the planning stage to implementation. All trades such as climate technology, electrics, home and sanitary technology are comprehensively matched together.

Our goal is to achieve a plug & play solution for the customer, which saves time and costs when setting it up and which works in an efficient and reliable manner, even when coping with difficult environmental conditions.

The range of climate and ventilation appliances are presented in overview groups. The essential features of our products are often adapted for very difficult environmental conditions in the industrial environment.

So-called heavy-duty versions for outdoor temperatures of -40°C to +57°C, and appliance structures suiting marine requirements or for conditions in oil and natural gas refinery systems make this possible.

Our supply programme also includes products for comfort air-conditioning, such as, split climate solutions for single and multiple areas as well as various coldwater generation systems.

We look forward to hearing from you and would be delighted to answer your questions and support you in any HVAC matters.

Our Team

Martin Egerer

+43 7248 62794 213

martin.egerer@gfoellner.at

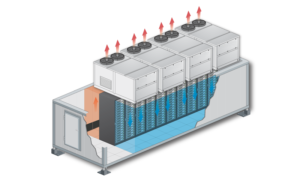

HVAC Rooftop Units

The units are mounted and installed on the roof of the container with direct cooling of the indoor over supply and return air openings. A framework system between the container roof and the HVAC Unit guarantees an air- and weatherproof tight connection between container and unit.

Due to space saving compact unit solution on the roof, several container modules can be coupled on side- or front wall. The control panels inside can be arranged in any way needed without having to watch out for spaces for various ventilation openings on side walls. The heat output extracted from the room via the refrigeration cycle can escape vertically via the condenser heat exchanger. This partition can also be designed as a free cooling system to perform cooling with ambient air when there´s a low outdoor temperature and no compressor operation. The main power supply as well as all control lines can be fed from the room directly to the air condition unit. The unit is pre-charged with refrigerant and controls are pre programmed.

No additional work is required on site, the HVAC unit just has to be lifted onto the container roof, connected to the electrical system and commissioned. (Plug&Play)

| Main features | |

|---|---|

| Unit device sizes in cooling performance from | 6,0 - 65,0 kW |

| Refrigerant | R410a or R134a |

| Room conditions | 27°C / 47% r. H. |

| Ambient temperature standard min./max. | -25°C to +58°C |

| Min. ambient temperature in special execution | -40°C |

| Main power supply standard | 400V-3ph-50Hz |

| Main power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE, (on request UL) |

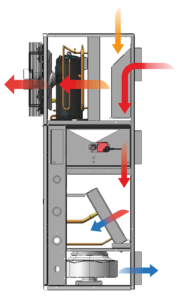

HVAC Compact Units - Outdoor

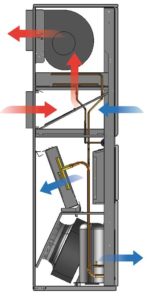

The installation is carried out on the lateral side of the container wall with direct cooling of the indoor over supply and return air openings. With regards to the supply air duct, you can choose between two different models. The supply air duct is either located in the middle of the unit by default or at the bottom of the unit to enable a horizontal air flow inside the room. As a special application, it´s possible to direct the cooling air down into an intermediate floor system to ensure evenly distributed air circulation inside the room.

The transition between container wall and HVAC unit is air and weatherproofed tight between the two elements. Due to the sidewall installation the units are accessible from the floor, which simplifies service and maintenance work. The control panels inside should be located in a way to have sufficient space on the side walls. This ensure air circulation over supply and return air openings in the container wall.

Depending on unit execution the heat output extracted from the room via the refrigeration cycle is discharged over the condenser heat exchanger freely upwards or horizontally downwards. Between the evaporator and condenser air flow a partition is available to prevent mixing of the two air systems. This partition can also be designed as a Freecooling-System to perform cooling at low outdoor temperature without compressor operation but with ambient air. The unit is pre-charged with refrigerant and includes pre programmed controls.

No additional work is required on-site. The HVAC unit just has to be installed on the container wall, connected to the electrical system and commissioned (Plug & Play).

| Main features | |

|---|---|

| Unit device sizes in cooling performance from Refrigerant | 3,5 - 35,0 kW |

| Refrigerant | R410a or R134a |

| Room conditions | 27°C / 47% r. H. |

| Ambient temperature standard min./max. | -25°C to +55°C |

| Min. Ambient temperature in special execution | -40°C |

| Main power supply standard | 400V-3ph-50Hz |

| Main power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE |

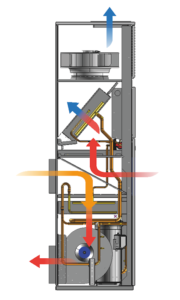

HVAC Compact Units - Indoor

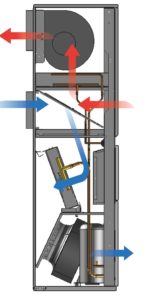

Installation inside the container is carried out with a direct supply of conditioned air into the room or the intermediate floor. The latter version guarantees specific and consistent air distribution. The return air is supplied from the front or from the upper part of the room to the unit. A return air duct junction is realizable. The heat output extracted from the room via the refrigeration cycle is discharged to the outside over supply and return air openings on the rear side of the unit. Between the evaporator and condenser air flow a partition is available to prevent mixing of the two air systems. This partition can also be designed as a Freecooling-System to perform cooling at low outdoor temperature without compressor operation but with ambient air. With this type of installation, it is necessary to have a free space on one of the walls inside the container or room.Wall openings to ensure free discharge of the warm air to the outdoor area are essential.

The transition between container wall and HVAC unit is air and weatherproofed tight between the two elements. Due to the indoor installation the units are easily accessible for service and maintenance work. Furthermore, the installation, commissioning and test run can already be carried out in the factory, so no work is required to be done on-site.

The control panels inside should be located in a way to have sufficient space on the side walls to install the units. The main power supply as well as all control cables can be fully wired in the factory, which ensures that no wiring errors can occur on-site. The unit is pre-charged with refrigerant and includes pre programmed controls. No additional work is required on-site

| Main features | |

|---|---|

| Unit device sizes in cooling performance from | 3,0 - 28,0 kW |

| Refrigerant | R410a or R134a |

| Room conditions | 27°C / 47% r. H. |

| Ambient temperature Standard min./max. | -25°C to +55°C |

| Min. ambient temperature in special execution | -40°C |

| Main Power supply Standard | 400V-3ph-50Hz |

| Main Power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE |

HVAC Split Units

The installation of the HVAC system is carried out separately: evaporator indoor unit and compressor condensing outdoor unit. To close refrigerant circuit both units are connected with refrigerant pipes made of copper tubes. The evaporator unit carries out the cooling of the room with the recirculation air. The extracted heat output is transported via refrigerant and copper tubes to the outdoor unit and discharged into the outside air. Depending on the container construction, the units can be installed on the ceiling or side walls. The installation of the outdoor unit can be carried out on the roof or with a console on the outside walls.

With this split unit system an extremely dense execution of the container room can be achieved, as only refrigerant, power and control lines have to be wired through the container walls. This air conditioning unit is a possible solution, especially when internal overpressure is generated or in case of high fire protection requirements. The service and maintenance work needs to be carried out on the indoor and on the outdoor unit. The control panels inside can be arranged in a way needed, as the indoor units can be installed on the ceiling.

Refrigeration works such as installation of refrigerant pipelines, filling the system with refrigerant and commissioning has to be done on-site. If required, it’s possible to completely pre-assemble the units in our factory and connect the indoor and outdoor units together with special valve connection kits. For transporting the container to the construction site, the outdoor units will be dismantled and can be easily assembled and commissioned on-site. Due this kind of installation preparation, there’s no skilled refrigerant technician needed on-site.

| Main features | |

|---|---|

| Unit device sizes in cooling performance from | 2,5 - 40,0 kW |

| Refrigerant | R410a or R134a |

| Room conditions | 27°C / 47% r. H. |

| Ambient temperature standard min./max. | -25°C to +57°C |

| Min. ambient temperature in special execution | -40°C |

| Main power supply standard | 400V-3ph-50Hz |

| Main power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE, (on request UL) |

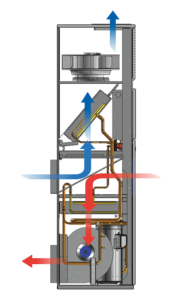

Close Control HVAC Units

Close control Units are mainly used for precision cooling in thermally high performance technical rooms like IT data centres, server rooms as well as laboratory and operating ranges. The execution of these systems is possible as a direct evaporator with external condenser heat exchanger, as water-cooled system for connecting to an existing cooling water system, or with external cooler.Cold water units supplied by their own chilled water system are also available. For the common split version the installation is carried out separately for the evaporator indoor and the condensation outdoor unit. To close the refrigerant circle, both units are connected with refrigerant pipes made of copper tubes. The evaporator unit carries out the cooling of the room through the recirculation air. Thereby the extracted heat output is transported via refrigerant and copper pipes to the outdoor unit and discharged into the outside air.

The field of application of the close control unit is in container or in permanent buildings. Therefore, the appropriate space for the unit needs to be considered in the room to be air conditioned and the arrangement of the control panels or racks has to be provided.

The conditioned air can be supplied into a raised floor system and evenly distributed throughout the room. Another variant is the supply air discharge freely upwards into the room or further via a connected air duct system for optimised uniform air distribution. In case of supply air outlet at the top of the unit it can be connected an air duct system or a plenum for horizontal air flow direction into the room.

The installation of the outdoor unit needs to be carried out with a roof or wall console. The service and maintenance work must be carried out on the indoor and on the outdoor unit.

Refrigeration works, such as, installation of refrigerant pipelines, filling the system with refrigerant and commissioning have to be done on-site.

| Main features - Direct expansion system | |

|---|---|

| Device sizes in cooling performances from | 4,0 - 135,0 kW |

| Refrigerant | R410a or R134a |

| Room conditions | 27°C / 47% r. H. |

| Ambient temperature Standard min./max. | -25°C to +57°C |

| Min. ambient temperature in special execution | -40°C |

| Main Power supply Standard | 400V-3ph-50Hz |

| Main Power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE |

| Main features - Cold water system | |

|---|---|

| Unit device sizes in cooling performance from | 4,0 - 550,0 kW |

| Refrigerant | R134a |

| Room conditions | 27°C / 47% r. H. |

| Cold water temperature | 7/12°C |

| Glycol | 0% |

| Main power supply Standard | 400V-3ph-50Hz |

| Main Power supply in special execution | 460V-3ph-60Hz |

| Design according to | CE |

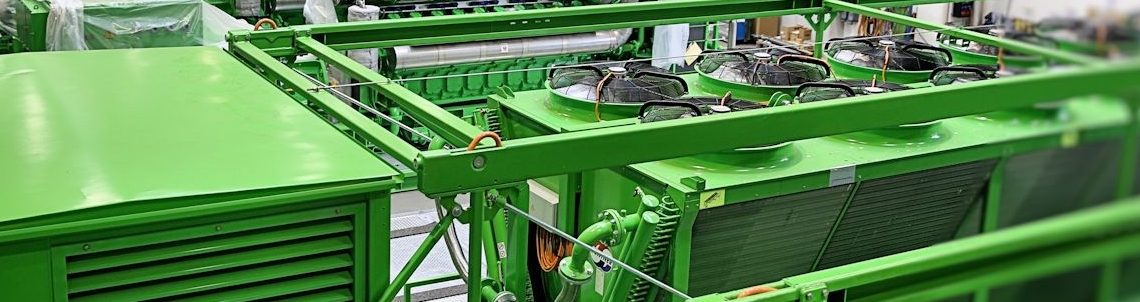

Chillers

These units can be installed outdoors (air-cooled version) or inside a space (water-cooled version). For cooling the circulating medium like water or a mixture of water/glycol, it is required to have a closed mechanical refrigerant circuit with the main components of compressor, evaporator and condenser to extract the transferred heat capacity from the medium. For outdoor installations heat will be carried to the condenser heat exchanger coil by the refrigerant and consequential to the outdoor ambient air. In case of installation of the chiller inside a room or building, the medium heat can be transferred to a water-side coupled recooling system. Chiller units are mainly used when a very high cooling capacity is required and less space available for generating chilled water.

Also, this system requires less amount of refrigerant to be used in case of a multiple split system with a high quantity of evaporating units. Chiller ensure in comparison to direct expansion system a better cost savings in use of refrigerant, higher energy efficiency and better sound absorption in case of a water cooled system. This covers applications in the industrial sector, production and manufacture, IT data centres as well as offices, residential buildings and hotels.

Due to the flexibility of our manufacturers, we are able to provide tailor-made solutions that operate efficiently with high COP and EER values enabling us to introduce them to the market as stationary as well as easy to transport mobile solutions.

| Main features - air cooled / water cooled - Water chillers | |

|---|---|

| Unit sizes for cooling capacities | 10,0 - 1420,0 kW |

| Refrigerant | R410a or R134a |

| Type of compressor | Scroll or mod. Screw |

| Ambient temperatures standard min./max | -25°C until +55°C |

| Min. ambient temperatures for special units | -40°C |

| Main power supply standard | 460V-3ph-50Hz |

| Main power supply special | 460V-3ph-60Hz |

| Design according to | CE |