Company

We create mobile solutions for the future

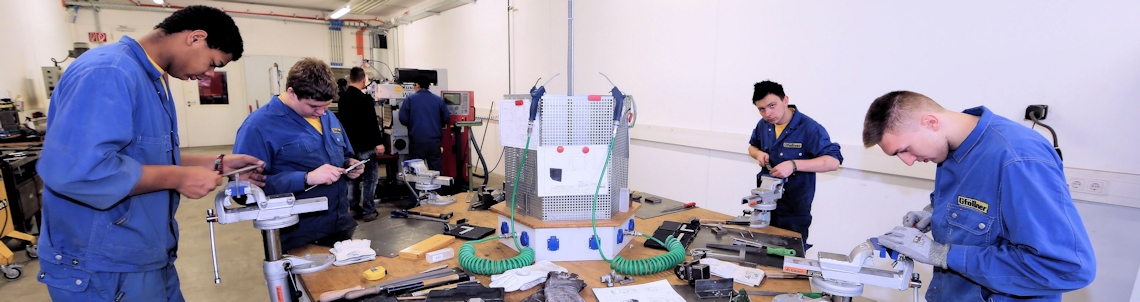

Gföllner has worked on with mobile solutions since its founding year of 1895. Today, owners KommR. Thomas Gföllner and DI(FH) Karl Pühretmair manage and constantly expand the company.

Our automotive and trailer engineering fulfills every transport requirement and has demonstrated its strengths in single-unit productions and limited-lot productions a thousand fold.

The in-house development department enables quick and individual adjustment. The range of products encompasses box bodies, combinable trailers to controlled truck trailers, and client-specific custom containers.

Figures, data, facts

| Employees total: | 380 |

| Apprentices: | 20 |

| Turnover 2023/24: | 75 Mio. € |

| Export share: | 75 % |

| Premises: | 13 ha |

| Production area: | 40.000 m² |

Company presentation

Modular components for the whole world

In 1970, the specialized field of "container technology" evolved from the successful area of custom automotive engineering and has produced more than 50,000 units for worldwide use until now.

Integrating, accepting, designing in a modular way, and transporting systems of all kinds, is best described with the expression "to contain". That's why the production of modular room cells is called "container technology" even today.

These room cells are used for everything from construction site facilities right up to transport of satellites. Particularly in power station construction, an increasing number of prefabricated components are produced, extended and tested at Gföllner.

In the case of large containers in lightweight construction, which are up to 25m long, 6m wide and can bear 50 tons, Gföllner has achieved market leadership in Europe. These modules are exported worldwide in cooperation with many renowned power station manufacturers, such as, GE, ABB, SIEMENS, ALSTOM, INNIO or Schneider Electric.

Certifications

| ISO 9001 | Quality management |

| EN ISO 3834-2 | Welding technology |

| DIN 2303 | Welding defence technology |

| DIN EN 15085-2 | Welding rail vehicles |

| DIN 6701-3 | Adhesive joints in rail vehicles |

| EN 1090 EXC 3 | Execution of steel structures |

| CSA Standard W47.1 - Division 1 | Welding of steel comonents for canadian market |